Don't miss our latest updates

Subscribe to our newsletter

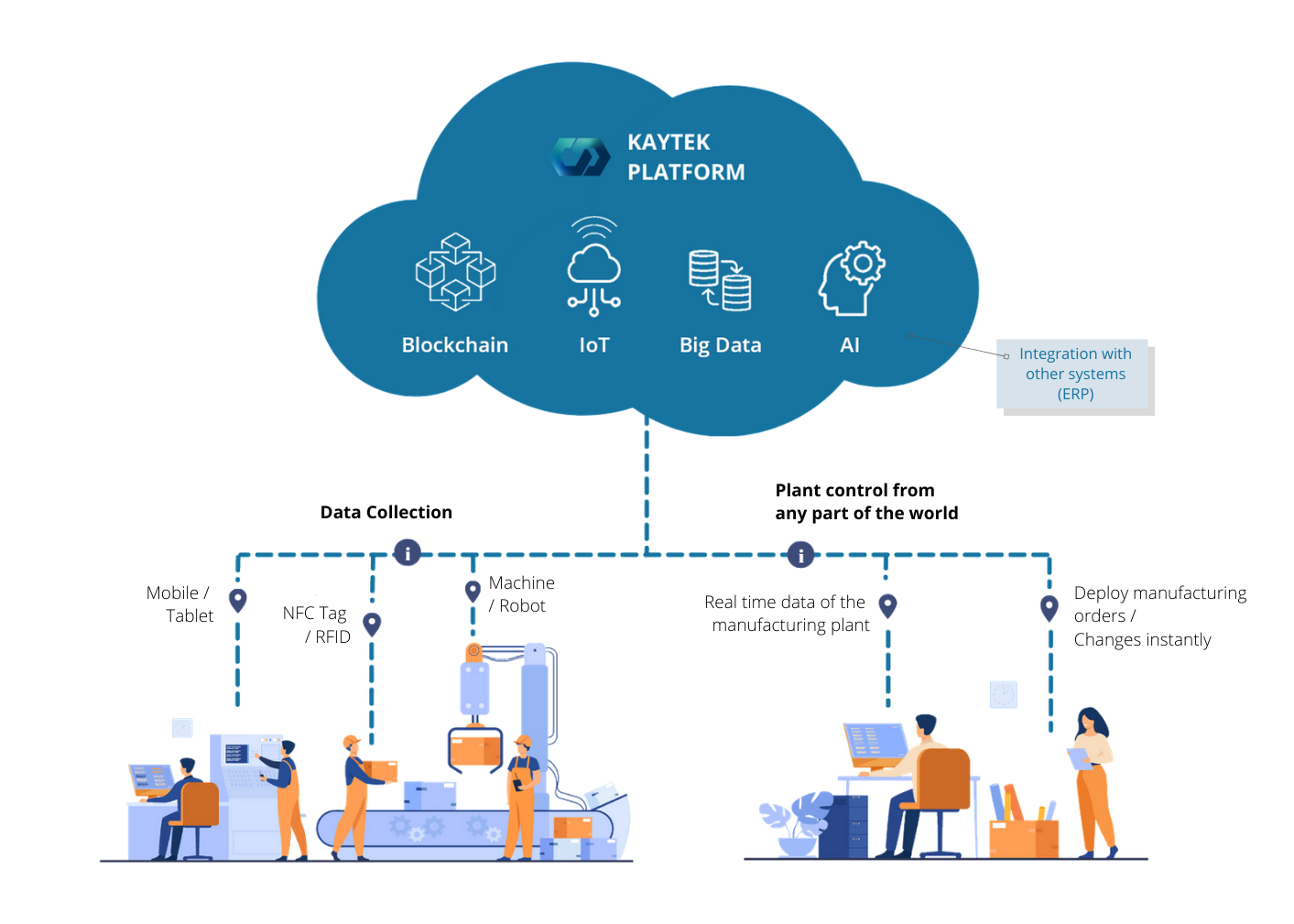

Certain technologies have become key enablers in pushing the industries towards a digital era. IoT, Artificial Intelligence, Blockchain and Big Data are leading technologies in this transformation.

Kaytek Platform incorporates those technologies at its core, allowing us to digitalize the industry in an easy way and to provide a Return of Investment in less than a year.

Internet of Things (IoT) is a technology that enables data collection from any kind of asset, such as machines, robots, humidity sensors, tools or raw materials. This allows us to have a full-traceability system for any asset, providing early alert detection, millisecond-level metrics capture, as well as high-value information to help with decision making.

Another main characteristic is the real-time data collection, ensuring tamper-free information and total absence of human error. The data is incorporated directly into the manufacturing processes. Quality measurements, compliance with standards and other requirements are fully automated, streamlining processes and decision making.

Real-time information

Alerts and incidents

Secure remote actions

Kaytek Platform is the ideal solution to make industrial environments more efficient, especially those where multiple companies work together to build a product. The processes are digitally defined and certified according to the standards of the regulations, as well as being stored and managed by Blockchain and Smart Contract technology.

Thanks to the Smart Contracts, the execution of the processes follows the definition in a very strict way, providing a complete traceability, which allows us to ensure that they are carried out in accordance with the regulations, guaranteeing the trustability of the data to all the actors. The technology is applicable to any kind of process; engineering, manufacturing or maintenance.

Immutability and secure data

Automatization - Smart Contracts

Unit-level traceability

Automated learning, pattern creation and anticipation of problems are some of the great challenges of the industry. Another great challenge is the sequencing of jobs in an optimal way or the improvement of production processes.

With the data obtained through the platform, we are able to generate mathematical models that are applied to the industry in an autonomous way. We provide a tool capable of anticipating problems, enabling the processes improvement and the optimization of resources consumption.

Early detection of anomalies and Preventive Maintenance planning

Root-cause identification of an error in production

Reduction of downtimes through smart operation sequencing

Industry 4.0 makes companies more complex and interconnected. The new generation machines and robots produce huge amounts of data that traditional systems are unable to handle.

Knowledge becomes an essential tool for correct decision-making. Kaytek Platform's Big Data technology allows us to process large volumes of data in real time, providing a constantly updated view of the production processes and indicators.

Storage of large volume of heterogenous data

Analysis of the information in real time

Dashboards and reports

Download our dossier with all the information.

"Kaytek has developed a platform that goes beyond a conventional BPMS and is unique for digitising industrial processes. Managing -even when on the move- traceability, optimizing production, reducing costs and training workers, are some of the aspects that make it different from the rest of the solutions on the market. In Auren we trust in Kaytek to offer our customers an innovative solution for the digitization of industrial processes, with which they can grow at their own rythm".

José Antonio Castaño

Consultancy Director at Auren

"It's obvious that Kaytek stands out as they have been leveraging cloud native technologies since their foundation, helping their customers go through the digital transformation and the adaptation process necessary for containerization to happen successfully."

Bart Farrell

Cloud Native Foundation Ambassador

"Kaytek allows us to collect data from the process in real time, collecting all the information necessary for a complete traceability of our the pieces, both from the information provided by the user and by the machines, which will allow us to improve the quality and costs of production in an increasingly demanding and competitive sector."

Pablo Escudero

General Manager at Fundiciones Fumbarri

"Kaytek has accompanied us on our way to implement open innovation projects, providing knowledge and experience. His high knowledge in cutting-edge technologies under IoT and Big Data environments have allowed us to successfully develop strategic projects. Using agile methodologies we have managed to transfer our needs and meet the objectives of our business."

Igor Urraza

Head of Infrastructure, Security and Communications at Vaillant Group

"Kaytek has been able to develop an agile, intuitive and easy-to-implement product for companies oriented towards the future standards of production management and its traceability. Production and updating of processes in real time. The future is here with Kaytek."

Gorka Retolaza

Head of programs and projects department at Aerometallic

"In a changing environment, it is a priority to work on the dynamization of processes, in collaboration with Kaytek we have managed to have a transparency of the production process in real time that helps us evaluate the state of the process together with the necessary improvements in time and costs, this together with a change in trends in the way our customers are supplied, leads us to a great leap in the digitization of our business."

Aitor Bernardo

MD Operations at Belgicast

Address

Fanderia street 2, 314 Module - 48901 Barakaldo - Spain

Contact form